Best Practices for Industrial Gutter Installation

March 22, 2025

Planning and Measurement

The first step in any gutter installation project, particularly in industrial settings, is careful planning and measurement. Accurate assessments of a building’s roof dimensions, slope, and other key characteristics are essential for designing a functional and efficient gutter system. Incorrect measurements can lead to poor water drainage, overflow issues, or even structural damage. When measuring the roof, it’s important to consider the slope of the roof. A roof with a steep incline requires a different type of gutter system compared to a flatter roof, due to the increased water flow and the possibility of debris accumulation.

An effective gutter system depends on the correct placement of downspouts and the gutter’s overall capacity to channel water away from the building. Overestimating or underestimating the size of the gutter can result in water overflow, which can damage the foundation of the building or create pooling that can lead to structural deterioration. Therefore, accurate measurements, including taking into account the roof’s angle, should be done before purchasing or installing the gutter system.

Material Selection

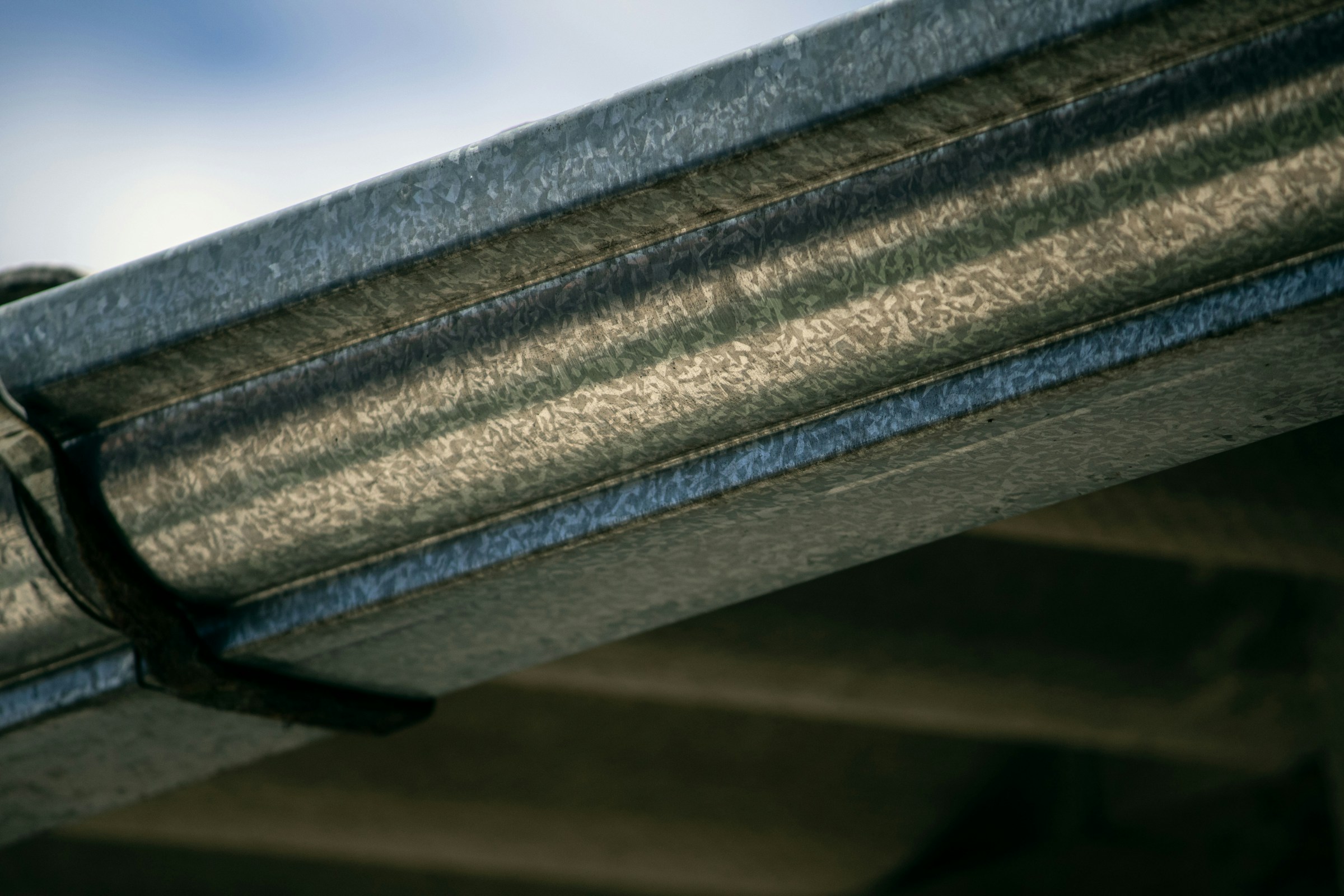

Selecting the right materials for industrial gutters is critical to the durability and effectiveness of the system. Common materials include aluminum, galvanized steel, copper, and vinyl. Among these, aluminum and galvanized steel are the most popular choices for industrial settings due to their resilience to harsh weather conditions.

Aluminum gutters are lightweight, corrosion-resistant, and cost-effective, making them a common choice for large buildings where affordability and longevity are key considerations. On the other hand, galvanized steel gutters, though heavier and more expensive, offer superior strength and durability, making them ideal for industrial settings with heavy rain or snow loads. Steel gutters are more prone to rusting over time, but with the proper coatings, they can be highly effective.

Choosing durable materials not only enhances the performance of the gutter system but also ensures that it withstands environmental stressors, such as extreme weather conditions, without requiring frequent repairs or replacements.

Proper Slope Calculation

A proper slope is essential to ensure that water flows smoothly through the gutter system toward the downspouts. The general rule is to aim for a slight slope of 1/4 inch for every 10 feet of gutter length. This slope ensures that water flows naturally toward the downspouts without pooling in the gutters, which could lead to overflow and damage the gutter system.

When installing gutters on an industrial building, it’s critical to achieve consistent slope and alignment across the entire length of the gutter system. This will ensure that water does not collect in areas where the slope may be insufficient, which could eventually result in a blockage or leakage. Additionally, the downspouts should be strategically placed to efficiently channel water away from the building’s foundation.

Secure Mounting

Industrial gutters are exposed to high winds, heavy rain, and large volumes of water, so secure mounting is paramount to ensuring the system remains intact. Gutter hangers and brackets should be chosen for their durability and ability to withstand heavy rainfall and pressure. These mounting systems should be spaced correctly according to the gutter size and type, as improper spacing can result in sagging or detachment from the building.

Additionally, the mounting system should allow for the expansion and contraction of the gutter material, especially in areas that experience temperature fluctuations. Metal gutters, for instance, will expand in hot weather and contract in colder conditions. A secure but flexible mounting system helps to accommodate these changes while keeping the gutters in place.

Exploring RainPro Gutters: Features and Benefits

High Capacity Design

RainPro gutters are designed to handle high water volumes, making them suitable for both residential and industrial applications. Their unique profile allows them to channel larger amounts of water than traditional gutters without being overly bulky. In industrial settings, where large roofs can accumulate significant amounts of rainwater, RainPro gutters offer an effective solution for preventing overflow.

The increased capacity of RainPro gutters is particularly important for preventing issues such as flooding or water pooling, which can lead to structural damage and foundation erosion. Additionally, the high-capacity design ensures that even in extreme weather conditions, the gutter system remains functional and efficient.

Aesthetic Appeal

While functionality is the top priority for industrial gutter systems, the aesthetic appeal of the system is also an important consideration. RainPro gutters strike a balance between performance and design, maintaining a sleek and modern appearance that complements the building’s exterior. This feature is valuable for industrial buildings that also need to maintain a professional, polished look while handling significant water drainage.

Durable Construction

RainPro gutters are manufactured with high-quality materials, ensuring long-lasting durability. These gutters are built to resist environmental elements such as extreme heat, cold, and heavy rainfall, ensuring they remain effective in various weather conditions. For industrial settings, where maintenance access may be limited, the durability of RainPro gutters can greatly reduce the need for frequent inspections or replacements.

MasterShield Gutter Protection: Advantages for Industrial Applications

Advanced Micro-Mesh Technology

MasterShield gutter guards utilize surgical-grade stainless steel micro-mesh that effectively blocks even the smallest debris from entering the gutters. This advanced technology makes MasterShield particularly useful in industrial applications where debris accumulation can be problematic. The micro-mesh prevents leaves, twigs, and other debris from clogging the gutter system, reducing the need for manual cleaning and ensuring that the gutters function efficiently.

The small mesh size also prevents pests from nesting in the gutters, another concern for industrial buildings that may attract animals. By preventing debris from entering the system, MasterShield gutter guards help maintain the integrity of the gutters, ensuring continuous, unimpeded water flow.

Self-Cleaning Design

One of the standout features of MasterShield gutter protection is its self-cleaning design. The system is built to shed debris naturally using gravity and airflow. This feature is especially useful in industrial settings, where regular cleaning may be challenging due to building height or accessibility issues. By allowing debris to flow off the system, the self-cleaning mechanism reduces the frequency and cost of manual maintenance, while also prolonging the life of the gutter system.

Enhanced Durability

MasterShield guards are designed to withstand the harshest weather conditions. The micro-mesh is infused with copper, which enhances the guard’s durability and resistance to corrosion. This feature is especially important for industrial gutters exposed to heavy rain, snow, or extreme temperatures. The copper infusion also helps prevent algae and mold growth, which can contribute to clogging and corrosion.

The Importance of Regular Maintenance for Industrial Gutters

Preventing Blockages

Regular maintenance is essential to keeping an industrial gutter system functioning properly. Over time, gutters can accumulate debris such as leaves, twigs, and dirt, which can block water flow and cause overflow issues. Routine inspections and cleaning can prevent these blockages and ensure that the system channels water effectively away from the building.

Without proper maintenance, gutters may become clogged, leading to water buildup that can overflow onto the building’s roof, walls, or foundation. Regular maintenance not only prevents blockages but also helps identify and fix small issues before they escalate.

Extending Lifespan

Routine maintenance is key to extending the lifespan of industrial gutters. Inspections allow property managers to spot early signs of wear and tear, such as loose hangers or rusting brackets, before they cause significant damage to the system. By addressing these minor issues early, the overall lifespan of the gutter system can be prolonged, reducing the need for costly repairs or replacements.

Protecting Structural Integrity

Well-maintained gutters help protect the structural integrity of a building by ensuring that water is directed away from the foundation. Overflowing or damaged gutters can lead to water pooling around the base of the building, which can cause cracks in the foundation, water infiltration into the walls, and other structural issues. Regular maintenance ensures that water is properly channeled away, safeguarding the building’s foundation and overall structural integrity.

Comparing Gutter Materials: Aluminum vs. Steel in Industrial Settings

Weight Considerations

When choosing between aluminum and steel gutters for an industrial building, weight is a key consideration. Aluminum gutters are lightweight, making them easier and faster to install. This can reduce labor costs and installation time. Steel gutters, while heavier, offer greater strength and can handle larger volumes of water, making them ideal for areas prone to heavy rainfall or snow.

Corrosion Resistance

Aluminum naturally resists rust and corrosion, making it an excellent choice for industrial environments exposed to moisture. Steel gutters, on the other hand, require galvanization or coating to prevent rusting. While steel gutters may provide better durability in high-impact situations, they can be more susceptible to corrosion if not properly coated or maintained.

Cost Implications

Aluminum gutters are typically more affordable than steel gutters, making them an attractive option for industrial buildings with budget constraints. However, while aluminum gutters may be less expensive upfront, steel gutters can offer a better return on investment in certain industrial environments where long-term durability and strength are more important.

The Role of Gutter Pitch and Alignment in Industrial Installations

Ensuring Optimal Water Flow

Proper gutter pitch and alignment are crucial for ensuring that water flows efficiently through the system. Gutters should be installed with a slight slope (typically 1/4 inch for every 10 feet of gutter) to ensure water flows toward the downspouts and away from the building. Without proper pitch, water may accumulate in certain areas, leading to overflow or standing water.

Reducing Maintenance Needs

Correctly installed gutters with appropriate pitch require less maintenance. Proper alignment ensures that water is directed away from the building, preventing water damage and reducing the need for frequent cleaning or repairs. Well-aligned gutters also prevent debris from accumulating in certain areas, which can clog the system and reduce its efficiency.

Preventing Structural Issues

Accurate gutter pitch and alignment prevent water from pooling near the foundation, which can cause structural damage over time. By directing water away from the building, properly installed gutters protect the foundation and exterior from water damage, which can be costly to repair.

Integrating Gutter Guards in Industrial Settings: Benefits and Considerations

Debris Prevention

Gutter guards prevent leaves, twigs, and other debris from entering the gutter system. This helps reduce the risk of clogs and ensures that water flows smoothly through the system. In industrial settings, where access to gutters can be difficult, gutter guards are especially useful for reducing the need for frequent cleaning and maintenance.

Maintenance Reduction

With gutter guards in place, the frequency of manual cleaning decreases, saving time and labor costs. Gutter guards reduce the buildup of debris, which means the system requires less attention and is less likely to need repairs or replacements.

Extended Gutter Lifespan

By preventing debris buildup and standing water, gutter guards help extend the overall lifespan of the gutter system. This is particularly important in industrial settings, where the cost of replacing a gutter system can be significant.

Addressing Common Challenges in Industrial Gutter Systems

Handling Heavy Rainfall

Industrial buildings, especially large warehouses and factories, can accumulate large volumes of water due to their size. Gutters must be designed with enough capacity to handle these large amounts of water without overflowing. Proper pitch and downspout placement are essential to ensuring that water is efficiently drained away from the building.

Preventing Ice Dams

In colder climates, ice dams can form in gutters, blocking water flow and causing potential damage to the gutter system. To prevent ice dams, heated gutter guards can be installed, or proper insulation can be added to the roof to prevent ice buildup.

Managing Debris Accumulation

Regular maintenance and the use of gutter guards can help manage debris and ensure that the gutter system remains functional. Gutter guards are particularly useful in industrial settings where manual cleaning may be challenging.

Innovations in Gutter Technology: What’s New?

Heated Gutter Guards

New technologies, such as heated gutter guards, are designed to prevent snow and ice buildup, ensuring continuous water flow during winter months. Heated guards help keep gutters free of ice dams, ensuring that the gutter system remains functional year-round, even in harsh winter conditions. These innovations can reduce maintenance costs and prevent potential damage to the building’s exterior.