How to Choose Between Aluminum, Steel, Copper, and Zinc for Industrial Seamless Gutters

December 18, 2024

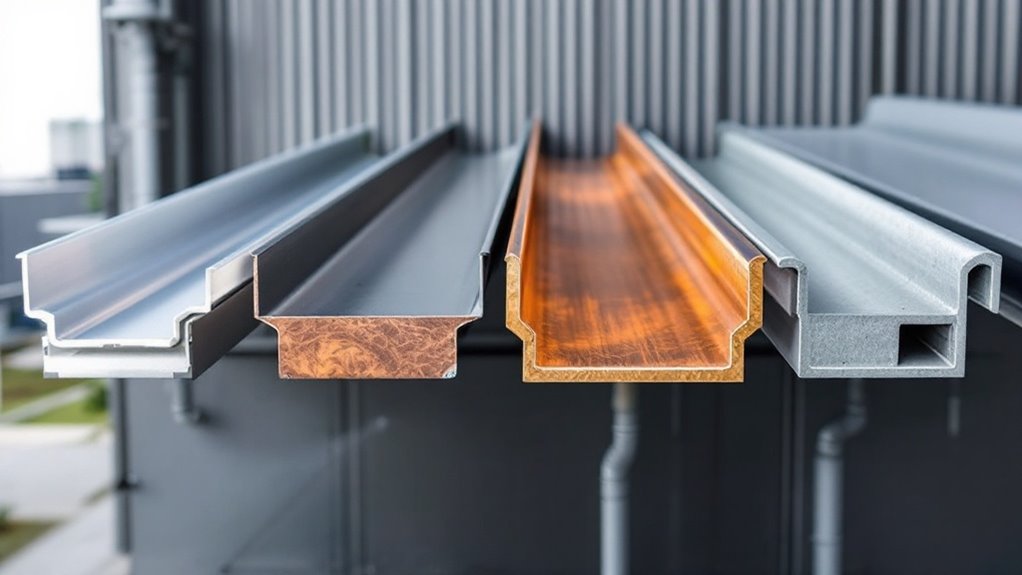

When choosing between aluminum, steel, copper, and zinc for industrial seamless gutters, consider several key factors. Aluminum gutters are lightweight, rust-resistant, and affordable, but may dent easily. Steel gutters are incredibly strong and durable, especially in heavy rainfall and snow, but require maintenance to prevent corrosion. Copper gutters offer an elegant appearance and excellent durability, though they are more expensive and require specialized installation. Zinc-coated options provide a balance of durability and affordability but need periodic inspections. Consider the material’s durability in your climate, aesthetic compatibility, cost, and maintenance needs to make an informed decision that will enhance your property’s performance and curb appeal. By weighing these factors, you can select the best material for your industrial seamless gutters and guarantee long-term satisfaction.

How to Choose Between Aluminum, Steel, Copper, and Zinc for Industrial Seamless Gutters

When selecting materials for industrial seamless gutters, it is crucial to take into account the unique demands and environmental conditions of your commercial property. Here are some key considerations for each material:

- Aluminum Seamless Gutters: Aluminum is lightweight, durable, and resistant to rust, making it a popular choice. It is affordable, easy to install, and available in various colors to match your building’s aesthetic. However, it may dent easily and is less durable than steel or copper.

- Steel Seamless Gutters: Steel gutters are incredibly strong and can withstand heavy rainfall and snow loads. They are available in galvanized or galvalume finishes to prevent rust. While more expensive than aluminum, they offer superior durability but require proper maintenance to prevent corrosion.

- Copper Seamless Gutters: Copper gutters are known for their elegant appearance and excellent durability. They are highly resistant to corrosion and can last for decades with proper maintenance. However, they come with a higher upfront cost and may require specialized installation.

- Zinc-Coated (Galvanized) Options: While not as commonly referred to as zinc alone, galvanized steel gutters are coated with zinc to prevent rust. They offer a balance between durability and affordability but may not be as long-lasting as copper or aluminum.

In a gutter material comparison, consider durability, aesthetics, cost, and maintenance requirements to guarantee you choose the best material for your industrial property.

Introduction

Selecting the right material for your industrial seamless gutters is a decision that impacts the longevity, maintenance, and overall performance of your gutter system. When considering options for your industrial seamless gutters, you must weigh the pros and cons of each material carefully. Copper seamless gutters, for instance, offer elegance and exceptional durability, developing a natural patina over time, but they come with a higher upfront cost and require professional installation.

Steel seamless gutters, including galvanized and galvalume steel, provide a balance between durability and affordability. They are strong, resistant to rust with proper maintenance, and available in various finishes to match your building’s style.

For industrial settings, aluminum seamless gutters are often preferred due to their lightweight, rust-resistant properties, and affordability. They are easy to install and maintain, making them a practical choice for commercial buildings. Each material has its unique advantages and considerations, so choosing the right one is vital for ensuring the long-term protection and efficiency of your industrial seamless gutters.

Selecting the right material for seamless gutters is crucial for the longevity and performance of industrial buildings. This article compares the benefits and drawbacks of aluminum, steel, copper, and zinc, helping business owners make an informed choice based on climate, budget, maintenance, and aesthetic needs

Choosing the right material for your industrial seamless gutters is paramount for ensuring the longevity and best performance of your building’s gutter system. When selecting a material, consider the durability, climate, budget, maintenance, and aesthetic needs of your industrial building.

Aluminum is a popular choice for seamless gutters due to its lightweight and rust-resistant properties. It is easy to install and comes in various colors, making it a versatile option. However, aluminum gutters can expand and contract with temperature changes, potentially leading to leaks.

Steel, particularly galvanized steel, offers durability and can be installed as seamless systems, reducing the risk of leaks. It is more resistant to heavy snowfall and hail but requires more maintenance due to the potential for rust once the zinc coating wears off.

Copper gutters are highly durable and low maintenance, with a lifespan of up to 100 years. They are resistant to extreme temperatures and do not rust or erode, but they are expensive and heavy.

Zinc gutters are also highly durable, with a natural patina that protects them from corrosion. They are UV-resistant and have an excellent lifespan, although they are pricier and less commonly used in residential settings.

Each material has its benefits and drawbacks, so it is crucial to weigh these factors against your specific needs for durable gutters for industrial buildings.

Aluminum Seamless Gutters

When considering aluminum seamless gutters for your industrial property, you’re opting for a lightweight yet durable material that is easy to install and maintain. Aluminum gutters are rust-proof, making them ideal for climates with high rainfall, and they come in a wide variety of colors to match your building’s aesthetic. However, be aware that aluminum gutters can expand and contract with temperature changes, which may lead to leakage issues if not properly installed and sealed.

Definition and Benefits

Aluminum seamless gutters are a top choice for industrial properties due to their exceptional durability and performance. Here’s why you should consider them:

Definition and Benefits

Aluminum seamless gutters are custom-made on-site to fit the exact dimensions of your building, eliminating seams and weak points. This design guarantees a smooth and efficient flow of water, reducing the risk of clogs and leaks.

Key Benefits

| Feature | Description | Benefit |

|---|---|---|

| Material | Lightweight, rust-resistant aluminum | Long-lasting, low maintenance |

| Design | Seamless, custom-fit | Reduces clogs and leaks |

| Performance | Withstands heavy rain, snow, and wind | Guarantees long-term durability |

Unlike zinc, steel, or copper gutters, aluminum seamless gutters offer a cost-effective solution without compromising on durability or aesthetic appeal. They are easy to install, resistant to corrosion, and can be color-matched to your building’s exterior, enhancing curb appeal while providing essential protection.

Aluminum gutters are lightweight, corrosion-resistant, and affordable, making them ideal for a range of industrial properties. Their smooth finish enhances curb appeal, and they are available in a variety of colors and finishes

When considering aluminum seamless gutters for your industrial property, you need to evaluate their durability and weather resistance. Aluminum gutters, particularly those made from high-grade .032 gauge material, are engineered to withstand harsh weather conditions, including heavy rains and extreme temperature changes, guaranteeing they remain intact and functional over the long term.

Their corrosion-resistant properties, combined with a baked-on paint finish, protect them from chipping, peeling, and flaking, maintaining their integrity even in challenging environments. This durability guarantees that your gutter system can handle the demands of industrial use without frequent repairs or replacements.

Durability and Weather Resistance

For industrial properties, selecting gutters that excel in durability and weather resistance is crucial to guarantee long-term protection and minimal maintenance. Each material has its unique strengths and weaknesses in this regard.

Durability and Weather Resistance Comparison

| Material | Durability | Weather Resistance |

|---|---|---|

| Aluminum | Lightweight, resistant to corrosion, but prone to dents and leaks over time. | Good resistance to weather, but may expand and contract, causing seams to leak. |

| Steel | More durable, keeps shape and profile longer, but requires maintenance to prevent rust. | Strong against harsh weather, but zinc coatings wear off over time, increasing rust risk. |

| Copper | Highly durable, lasts for decades with minimal upkeep, resistant to corrosion. | Excellent weather resistance, maintains integrity in harsh conditions. |

| Zinc | Long-lasting, forms a patina that makes it UV and corrosion resistant. | Superior weather resistance, lasts longer than copper in some cases. |

When choosing industrial seamless gutters, consider these factors to guarantee you select the most suitable, long-lasting gutter solutions for your industrial building.

Aluminum is highly resistant to corrosion and performs well in regions with moderate to heavy rainfall. However, it may dent or bend under extreme impact

When considering aluminum gutters for your industrial property, you need to weigh the costs and maintenance requirements. While aluminum gutters are affordable and resistant to corrosion, they may require more frequent inspections to guarantee they haven’t dented or bent due to extreme weather conditions or impact. Regular maintenance, such as clearing debris and checking for damage, can help extend the lifespan of these gutters and prevent costly repairs.

Cost and Maintenance

Choosing the right material for your industrial seamless gutters involves a careful consideration of both cost and maintenance. When it comes to the cost of seamless gutters, aluminum is generally the most affordable option, making it a popular choice for industrial properties. It is lightweight, easy to install, and resistant to rust, which helps keep long-term costs down.

For gutter maintenance, aluminum gutters require minimal upkeep, as they do not rust and are less prone to corrosion compared to steel. However, they can dent or bend under extreme impact, so regular inspections are necessary to guarantee they remain in good condition. Steel gutters, such as galvanized or Galvalume, are more durable but require more maintenance to prevent rust, especially in areas with high moisture or extreme temperature fluctuations.

Copper and zinc gutters, while more expensive, offer long-term durability and a unique aesthetic, but they also need periodic checks to guarantee their patina does not lead to any underlying issues. Proper maintenance of industrial property gutters is vital to guarantee they continue to protect your building from water damage and structural issues. Regular cleaning and inspections can substantially extend the lifespan of your gutters, regardless of the material chosen.

Aluminum gutters are one of the most cost-effective options, offering great value for money due to their long-lasting nature and minimal maintenance needs

When considering the aesthetic appeal and environmental impact of aluminum gutters, you should note that they come in a wide variety of colors to match your building’s design, ensuring a seamless integration with the existing architecture. From an environmental perspective, aluminum gutters are highly recyclable, making them a sustainable choice for industrial properties. Additionally, their long lifespan and minimal maintenance needs reduce the need for frequent replacements, contributing to a lower overall environmental footprint.

Aesthetic Appeal and Environmental Impact

Industrial seamless gutters, particularly those made from aluminum, steel, copper, and zinc, not only provide robust functionality but also substantially enhance the aesthetic appeal of commercial properties. When considering gutter aesthetics, aluminum gutters are often the preferred choice due to their lightweight and rust-resistant properties, available in a variety of colors and finishes that can match or complement your building’s exterior. Copper and zinc gutters, while more expensive, offer a unique patina that can add a touch of elegance and character over time.

From an environmental perspective, these materials are relatively environmentally friendly. Aluminum and steel gutters are recyclable, making them a sustainable option. Copper and zinc, although more costly, are highly durable and require less frequent replacement, reducing the environmental impact of frequent material replacements. Additionally, rain protection systems like those offered by ASG Seamless Gutters guarantee efficient water management, helping to conserve water resources and protect the surrounding environment.

Aluminum gutters are available in a wide range of colors, and they are recyclable, making them a sustainable choice for eco-conscious businesses

Aluminum gutters, a staple in industrial gutter systems, offer a versatile and sustainable solution for businesses. One of the key benefits of aluminum gutters is their availability in a wide range of colors, allowing you to match or complement your building’s exterior. This versatility is particularly useful for maintaining or enhancing the aesthetic appeal of your property.

Here are some key points to ponder:

- Color Variety: Aluminum gutters come in nearly twenty different colors, from neutral tones like Royal Brown and Pearl Gray to more vibrant options like Traditional Blue and Forest Green.

- Recyclability: Aluminum is highly recyclable, making it an eco-friendly choice for businesses aiming to reduce their environmental footprint.

- Durability: Aluminum gutters are rust-proof and can last over 20 years with proper maintenance, ensuring long-term performance and reduced replacement costs.

- Low Maintenance: Seamless aluminum gutters are designed to be low maintenance, eliminating the need for frequent repairs and re-sealing.

Steel Seamless Gutters

When considering steel seamless gutters for your industrial property, you’re opting for a highly durable and strong option that can withstand heavy rainfall and snow loads. Steel gutters are available in various finishes to match your building’s style and are coated to prevent rust and corrosion, guaranteeing long-term performance. However, it’s vital to guarantee proper maintenance to prevent rust, as this can affect their longevity and overall efficiency.

Definition and Benefits

Steel seamless gutters are a robust and reliable choice for industrial properties, offering superior durability and weather resistance. These gutters are crafted from high-grade steel, making them ideal for withstanding harsh weather conditions and heavy rainfall.

Here are some key benefits of steel seamless gutters:

- Long-Term Durability: Steel gutters can last over 20 years with minimal maintenance, ensuring long-term protection for your industrial property.

- Enhanced Weather Resistance: Steel gutters are resistant to bending, tearing, and rusting, providing a robust defense against rain, snow, and extreme weather.

- Reduced Maintenance: The seamless design eliminates weak points where debris can accumulate, reducing the need for frequent cleaning and maintenance.

- Superior Strength: Steel gutters are stronger than other materials, ensuring they can handle the demands of large commercial buildings without sagging or pulling away from the structure.

Steel gutters, particularly galvanized or stainless steel, are known for their strength and durability. They are best suited for harsh weather conditions and extreme climates

When considering steel gutters, particularly galvanized or stainless steel, you’re investing in materials renowned for their exceptional durability and weather resistance. Galvanized steel gutters, coated with a thin layer of zinc, are highly resistant to rust and can withstand harsh weather conditions, including freezing temperatures and heavy rains, without suffering from thermal warping or significant damage.

Stainless steel gutters, although less common due to higher costs, offer unparalleled corrosion resistance and a long-lasting sheen, making them ideal for extreme climates. Both types are less likely to crack under pressure from wind gusts, falling branches, or accumulated debris, ensuring your industrial gutters remain efficient and reliable over many years.

Regular maintenance, such as applying protective coatings, can further extend the lifespan of these gutters, particularly in regions with high humidity or frequent moisture exposure.

Durability and Weather Resistance

In regions prone to harsh weather conditions and extreme climates, the durability and weather resistance of steel gutters, particularly those made from galvanized or stainless steel, make them an exemplary choice. Galvanized steel, coated with a protective layer of zinc, enhances durability and resistance to corrosion, allowing these gutters to withstand moisture and harsh weather conditions effectively.

Here are key points to ponder for each material:

- Steel Gutters: Offer high strength and durability, suitable for extreme climates. Require regular maintenance to inspect and maintain the zinc coating.

- Aluminum Gutters: While durable, they are more prone to leakage due to expansion and contraction. They are rust-proof but require monitoring for dents and leaks.

- Copper Gutters: Highly durable and low maintenance, but expensive. They develop a patina over time and require copper fittings to avoid galvanic corrosion.

- Zinc Gutters: Last longer than copper, with a UV and corrosion-resistant patina. They have an industrial appearance and are often used commercially.

Steel gutters can withstand heavy snow, ice, and severe weather conditions. However, they require periodic maintenance to prevent rust, particularly in humid or coastal areas

When considering steel gutters for your industrial property, you need to factor in the cost and maintenance requirements. While steel gutters are highly durable and can withstand heavy snow, ice, and severe weather conditions, they do come with a higher upfront cost compared to other materials. Additionally, you’ll need to perform periodic maintenance to prevent rust, especially in humid or coastal areas, which can add to the long-term expenses.

Cost and Maintenance

Steel gutters, renowned for their resilience in withstanding heavy snow, ice, and severe weather conditions, come with specific cost and maintenance considerations. While they are more expensive than aluminum gutters, their resilience can justify the higher cost. However, to maintain their integrity, you need to guarantee they remain free from rust.

Here are some key points to ponder:

- Initial Cost: Steel gutters are generally more expensive than aluminum but less expensive than copper or zinc.

- Maintenance Needs: Regular cleaning and removal of standing water are vital to prevent rust, especially in humid or coastal areas.

- Coating Durability: Galvalume and stainless steel gutters offer better corrosion resistance compared to galvanized steel, but may still require occasional inspection and maintenance.

- Installation Complexity: Steel gutters can be heavier and more challenging to install, which may add to the overall cost and require specialized labor.

Steel gutters are moderately expensive compared to aluminum, with galvanized steel being more affordable than stainless steel. Regular maintenance is needed to preserve their protective coating

When considering the aesthetic appeal and environmental impact of steel gutters, you should note that galvanized steel offers a unique mill finish that can complement various architectural styles, including contemporary and industrial designs. The zinc coating on galvanized steel not only enhances durability but also provides an antifungal property, preventing the growth of fungus, mold, and bacteria. Additionally, at the end of their lifecycle, galvanized steel gutters can be fully recycled, making them a more environmentally friendly option compared to some other materials.

Aesthetic Appeal and Environmental Impact

When choosing industrial seamless gutter materials, the aesthetic appeal and environmental impact are crucial factors to take into account.

Aluminum gutters, for instance, come in a variety of colors and finishes, making them versatile for matching existing building designs. They are also lightweight and easy to install, which can reduce the overall environmental footprint of the installation process.

Here are some key points to think about:

- Color and Finish: Aluminum and galvalume gutters can be pre-finished with baked-on enamel paint, ensuring a long-lasting color that matches your building’s aesthetic.

- Corrosion Resistance: Zinc gutters develop a protective patina over time, but they may not be ideal in coastal areas due to saltwater degradation. Stainless steel gutters maintain their shiny appearance and are highly resistant to corrosion.

- Environmental Impact: Copper gutters, though expensive, are a recyclable material and can be a sustainable choice. However, their high cost may outweigh this benefit for some projects.

- Material Durability: Galvalume gutters, with their zinc and aluminum coating, are durable and resistant to high temperatures and severe weather conditions, minimizing the need for frequent replacements.

Steel gutters provide a rugged industrial look and are 100% recyclable, although they have a higher environmental cost due to energy-intensive manufacturing processes

If you’re considering steel gutters for your industrial property, you’re opting for a material that offers a rugged, industrial look and significant environmental benefits, despite some drawbacks. Steel gutters are 100% recyclable, making them a sustainable choice for long-term use. However, their production involves energy-intensive manufacturing processes, which increase their environmental cost.

Steel gutters are highly durable and resistant to corrosion, especially when galvanized with a zinc coating. This coating protects the steel from rust, ensuring the gutters maintain their shape and profile over time. While steel is heavier than aluminum and more prone to rust if the zinc coating wears off, it is harder to dent and can withstand harsh weather conditions, including heavy snowfall and hail. This durability makes steel gutters a reliable option for industrial properties, despite the higher initial environmental impact of their production.

Copper Seamless Gutters

When considering copper seamless gutters for your industrial property, you’re opting for a material that combines exceptional durability with a unique aesthetic appeal. Copper gutters resist underside corrosion, last for over 50 years with proper maintenance, and are highly recyclable, making them an eco-friendly choice. They also naturally resist rust, moss, and algae, reducing the need for frequent maintenance and ensuring long-term performance against various weather conditions.

Definition and Benefits

Copper seamless gutters are a premium choice for industrial and commercial properties, offering a blend of durability, aesthetic appeal, and efficient rainwater management. When considering copper for your gutter system, you’re investing in a material that is highly resistant to rust, corrosion, and damage from extreme weather conditions.

Here are some key benefits of copper seamless gutters:

- Long-term Durability: Copper gutters can last for several decades, outperforming many other materials and providing long-term protection for your property.

- Low Maintenance: Copper is an algaecide and fungicide, preventing moss and other growth that can block the system, and it is not susceptible to underside corrosion.

- Aesthetic Appeal: Copper adds a sophisticated look to your property and can be integrated into various designs, enhancing the curb appeal of your building.

- Eco-Friendliness: Copper is fully recyclable and can be part of rainwater harvesting systems, promoting sustainable practices and reducing environmental impact.

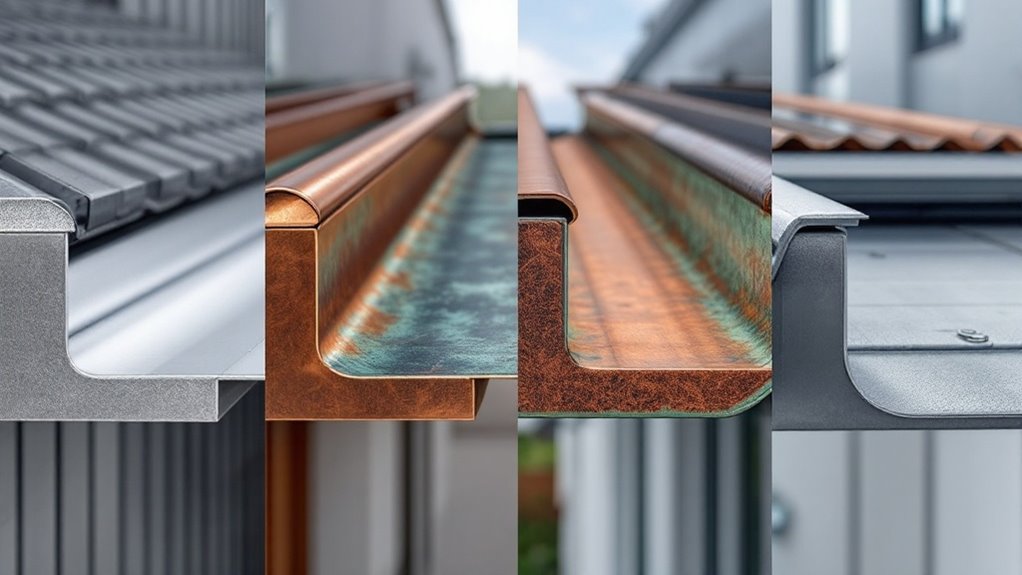

Copper gutters offer high-end aesthetics and superior durability, with a lifespan exceeding 50 years. The natural aging process of copper creates a distinctive patina that enhances a building’s appearance

When considering copper gutters for your industrial property, you’ll benefit from their exceptional durability and weather resistance. Copper gutters can withstand extreme weather conditions, including heavy rain, snow, and ice, without corroding or deteriorating over time. This resilience guarantees that your building’s gutter system remains intact and functional, even in the harshest environmental conditions.

Durability and Weather Resistance

Considering the stringent demands of industrial settings, the durability and weather resistance of gutter materials are paramount. When choosing between aluminum, steel, copper, and zinc for your industrial seamless gutters, it is essential to evaluate how each material performs under harsh conditions.

Key points to ponder:

- Aluminum: Resistant to corrosion, aluminum gutters are lightweight and can withstand moderate weather conditions, but may not be as strong as other materials in extreme cases.

- Steel: Known for its high strength, steel gutters are ideal for areas with heavy winds or hail, but they require more maintenance due to the risk of rust.

- Copper: Exceptionally durable and resistant to corrosion, copper gutters can withstand extreme weather conditions, including heat, cold, and heavy precipitation, with minimal maintenance required.

- Zinc: Offers a balance of strength and corrosion resistance, making it suitable for various weather conditions, though it may require occasional maintenance to prevent patina formation.

Each material has its strengths and weaknesses, so selecting the right one depends on the specific needs and environmental conditions of your industrial property.

Copper is resistant to corrosion and performs excellently in all weather conditions. It requires minimal maintenance, and the patina naturally protects the gutter from further damage

When considering the cost and maintenance of copper gutters, you should note that while the initial investment is higher, the long-term benefits are significant. Copper gutters require minimal maintenance due to their natural patina, which protects them from corrosion and weathering. This reduced maintenance need translates to lower long-term costs, making copper a cost-effective choice despite the upfront expense.

Cost and Maintenance

Choosing copper gutters for your industrial property comes with substantial cost and maintenance factors. While copper is highly durable and resistant to corrosion, it is one of the most expensive gutter materials available. Here are some key points to ponder:

Cost and Maintenance Factors

- High Initial Expense: Copper gutters are considerably more expensive than aluminum, steel, or zinc options, making them a substantial upfront investment.

- Minimal Upkeep: Despite the high expense, copper gutters require minimal upkeep due to their natural resistance to corrosion and the protective patina that forms over time.

- Durability: Copper gutters can last for 50 years or more, which can offset the initial expense over the long term.

- Specialized Installation: Copper gutters often require specialized installation techniques and materials to guarantee they are properly sealed and protected from other metals that could cause corrosion.

Copper is the most expensive gutter material but offers unparalleled longevity and low-maintenance performance

When considering copper gutters for your industrial property, you should be aware that they are the most expensive option, typically costing $15 to $30 per linear foot. However, this higher upfront cost is offset by their unparalleled longevity, with copper gutters lasting 60 to 90 years or more when properly maintained. This long lifespan and low-maintenance requirement make copper gutters a valuable investment for long-term performance and minimal upkeep.

Aesthetic Appeal and Environmental Impact

Copper gutters stand out for their exceptional aesthetic appeal and environmental benefits, making them a compelling choice for industrial properties. The natural patina that forms on copper gutters over time adds a unique and attractive element to the building’s exterior. Here are some key points to ponder:

- Natural Patina: Copper gutters develop a beautiful, protective patina that enhances their appearance and provides additional corrosion resistance.

- Sustainable Material: Copper is a recyclable and reusable material, making it an environmentally friendly option.

- Low Maintenance: The patina on copper gutters reduces the need for frequent painting or coating, lowering maintenance costs.

- Durability: Copper gutters are highly durable and can last for decades, reducing the need for frequent replacements and the environmental impact associated with them.

When choosing between materials, these aesthetic and environmental benefits of copper gutters can substantially influence your decision.

Copper’s natural beauty and patina make it a highly sought-after option for prestigious buildings. Despite being recyclable, its mining process is more environmentally costly compared to aluminum and zinc

For industrial and prestigious buildings, the allure of copper gutters lies in their natural beauty and the distinctive patina that develops over time. However, despite their aesthetic appeal and the fact that copper is 100% recyclable, the mining process for copper is more environmentally costly compared to aluminum and zinc.

Copper’s recyclability is a significant environmental benefit, as it can be recycled multiple times without losing its quality, and the recycling process uses less energy than extracting new copper. Yet, the initial extraction of copper involves considerable environmental impact, including energy consumption and potential habitat disruption.

When considering copper gutters, it is crucial to weigh these factors against the long-term durability and sustainability of the material, as well as its ability to support rainwater harvesting and reduce maintenance needs.

Zinc Seamless Gutters

When considering zinc seamless gutters for your industrial property, you’re opting for a material that offers exceptional durability and a long lifespan, often lasting between 80 and 100 years. Zinc gutters develop a natural protective patina that shields them from the elements and hides minor scratches, making them a low-maintenance choice. Additionally, zinc is highly sustainable, fully recyclable, and resistant to corrosion, making it an excellent option for areas with varying weather conditions.

Definition and Benefits

How do zinc seamless gutters stand out as a premium choice for industrial properties? Zinc seamless gutters are renowned for their exceptional durability, corrosion resistance, and low maintenance requirements, making them an ideal option for industrial settings.

Here are the key benefits of zinc seamless gutters:

- Longevity: Zinc gutters can last between 80 and 100 years, offering a long-term solution that minimizes the need for frequent replacements.

- Corrosion Resistance: Zinc forms a natural protective patina that shields it from the elements, ensuring it doesn’t rust or corrode.

- Self-Healing Properties: Minor scratches or blemishes on the zinc surface are naturally covered by the patina, maintaining a uniform appearance.

- Eco-Friendly: Zinc is fully recyclable, requires less energy to produce, and eliminates the need for chemical treatments or coatings, reducing its environmental impact.

Zinc gutters are durable, low-maintenance, and resistant to weathering. The material develops a unique matte gray patina over time, giving it a rustic charm that is particularly appealing in modern industrial settings

When considering zinc gutters for your industrial property, you’ll appreciate their exceptional durability and weather resistance. Zinc gutters develop a protective patina over time, which not only enhances their appearance but also shields them against corrosion and hail damage, ensuring they can last for 40-50 years with minimal maintenance.

This natural patina acts as a self-healing layer, repairing minor scratches and maintaining a uniform appearance, which is essential for withstanding harsh weather conditions common in industrial settings.

Given their inherent resistance to rust and corrosion, zinc gutters are an excellent choice for areas with fluctuating temperatures or coastal regions, providing long-term protection and reducing the need for frequent repairs or replacements.

Durability and Weather Resistance

Zinc gutters stand out for their exceptional durability and resistance to various weather conditions, making them an ideal choice for industrial properties. When considering the durability and weather resistance of gutter materials, here are some key points to keep in mind:

- Long-Term Endurance: Zinc gutters can last between 50 to 100 years with proper maintenance, outlasting many other materials.

- Weather Resistance: Zinc develops a protective patina that shields it from corrosion, hail, and other impacts, ensuring it remains intact through harsh weather conditions.

- Low Maintenance: Despite its durability, zinc requires minimal upkeep, as it naturally resists moss, mold, and mildew, and its patina self-heals minor scratches.

- Climate Adaptability: Zinc gutters are suitable for various climates, though they may not be ideal for coastal areas due to saltwater corrosion.

These characteristics make zinc an excellent option for industrial seamless gutters, ensuring long-term protection and minimal maintenance needs.

Zinc gutters are strong, resistant to corrosion, and perform exceptionally well in coastal and extreme weather environments

When considering zinc gutters for your industrial property, you’ll find they offer significant cost and maintenance benefits. Zinc gutters are highly resistant to corrosion, which reduces the need for frequent repairs and replacements, thereby lowering long-term maintenance costs. Additionally, the protective patina that forms on zinc gutters enhances their durability, making them a cost-effective choice that requires minimal upkeep.

Cost and Maintenance

Choosing the right material for your industrial seamless gutters is crucial, especially when evaluating the long-term costs and maintenance requirements.

When assessing the cost and maintenance of different gutter materials, here are key points to ponder:

- Aluminum Gutters: Generally the most affordable option, aluminum gutters are lightweight and resistant to rust. They require minimal upkeep, as they do not rust and can withstand various weather conditions. However, they may be thinner than steel and more susceptible to damage from hail.

- Steel Gutters: While robust and able to withstand heavy weather, steel gutters, especially galvanized steel, require more upkeep to prevent rust. The zinc coating on galvanized steel eventually wears off, necessitating regular cleaning and inspection to remove standing water.

- Copper Gutters: Copper gutters are the most expensive option but require very little upkeep due to their natural resistance to corrosion. They develop a protective patina over time but can be costly to install.

- Zinc Gutters: Although zinc gutters are highly durable and resistant to corrosion, they are more expensive than aluminum. They do not require frequent upkeep but can react poorly with certain materials like cedar shingles or coastal environments.

Ensuring your gutters are properly maintained can substantially extend their lifespan and protect your building from water damage.

Zinc gutters fall between aluminum and copper in terms of cost. They require little maintenance, as the natural patina helps protect against corrosion

When considering zinc gutters for your industrial property, you’ll find they offer a balanced mix of cost and performance, falling between aluminum and copper regarding expense. The natural patina that forms on zinc gutters not only enhances their aesthetic appeal but also provides significant corrosion resistance, reducing the need for frequent maintenance. From an environmental perspective, zinc gutters are highly sustainable, as zinc can be recycled indefinitely without losing its properties, and the manufacturing process consumes less energy compared to other metals.

Aesthetic Appeal and Environmental Impact

Zinc gutters offer a unique blend of aesthetic appeal and environmental sustainability, making them an attractive option for industrial properties. The natural patina that forms on zinc gutters adds a distinctive, elegant look that can enhance the visual appeal of your building.

Here are some key considerations for the aesthetic and environmental impacts of different gutter materials:

- Aluminum Gutters: Lightweight and available in various colors, aluminum gutters are durable and resistant to rust. However, they may not offer the same aesthetic depth as other materials.

- Steel Gutters (Galvalume): Galvalume gutters maintain their shine and are resistant to corrosion, but they can be heavy and may not be suitable for coastal areas due to saltwater degradation.

- Copper Gutters: Copper gutters provide a luxurious appearance but are more expensive. They are highly durable and can be recycled, reducing environmental impact.

- Sustainable Materials: Using recycled materials, such as aluminum and plastic composites, can minimize the environmental impact of gutter production and enhance their longevity.

Zinc gutters offer a distinctive appearance with their matte gray patina and are highly recyclable with a lower environmental impact compared to copper and steel

Zinc gutters, with their distinctive matte gray patina, offer a unique aesthetic appeal that complements various architectural styles. This natural patina process eliminates the need for chemical treatments or coatings, reducing the environmental impact. Zinc is highly recyclable, making it an eco-friendly choice. Unlike some other materials, zinc requires less energy to produce and can be fully recycled at the end of its life, a trait it shares with copper but often at a lower cost.

When considering environmental impact, zinc gutters stand out. They are 100% recyclable, and in regions like Western Europe, nearly 99% of zinc roofs and walls are recycled. This recyclability, combined with zinc’s durability and long lifespan, makes it a sustainable option that minimizes waste and reduces the need for frequent replacements.

Factors to Consider When Choosing the Right Material for Your Industrial Seamless Gutters

When selecting the right material for your industrial seamless gutters, consider the climate and weather conditions of your region. If you are in an area prone to heavy rainfall, frequent snowfall, or intense storms, you may need gutters with a larger capacity, such as box-style or wide K-style gutters made from durable materials like aluminum or galvanized steel.

In regions with heavy snowfall, galvanized steel gutters might be more suitable due to their robust nature and ability to withstand harsh weather conditions. Conversely, areas with moderate rainfall can often suffice with aluminum or zinc gutters, which are lighter and still highly effective.

Ensuring the material aligns with your local weather patterns is vital for the long-term performance and durability of your gutter system.

Climate and Weather Conditions

Choosing the right material for your industrial seamless gutters starts with a thorough assessment of your local climate and weather conditions. Climate change has intensified weather patterns, leading to heavier rainfall, more frequent storms, and extreme temperature fluctuations. Here are key factors to consider:

Climate and Weather Considerations

- Heavy Rainfall and Storms: Materials like aluminum and steel are durable and can withstand heavy rains and strong winds without compromising their structural integrity.

- Temperature Fluctuations: Aluminum, being resistant to corrosion and able to withstand temperature changes, is a viable option to prevent joint failure and leaks.

- Debris Accumulation: In areas with heavy tree coverage, materials that are easy to clean and maintain, such as aluminum, can help prevent clogs and guarantee optimal water flow.

- Corrosion Resistance: Materials like zinc and copper offer natural corrosion resistance, which is essential in regions with high humidity and salt exposure.

Consider the climate in your area. Steel and zinc are best for harsh winters with heavy snow and ice, while aluminum and copper are suited for milder climates

When considering the climate for your industrial seamless gutters, you must also think about the budget implications of your material choices. Steel and zinc, though ideal for harsh winters with heavy snow and ice, are generally more expensive than aluminum and copper, which are better suited for milder climates. Understanding these cost differences will help you balance durability and weather resistance with your financial constraints.

Budget Considerations

When planning the installation of industrial seamless gutters, budget considerations must be closely tied to the climate of your area. Here are some key points to take into account:

Budget Considerations

- Aluminum Gutters: These are generally the most affordable option, lightweight, and resistant to rust. They are ideal for milder climates and can be seamlessly installed, reducing labor costs.

- Steel Gutters: While more durable and suitable for harsh winters, steel gutters are slightly more expensive than aluminum. They require more maintenance to prevent rust, which can add to the overall cost.

- Copper Gutters: Copper is one of the most expensive materials, known for its durability and aesthetic appeal. However, it can be a worthwhile investment for its long lifespan and low maintenance requirements.

- Zinc Gutters: Zinc gutters are also on the higher end of the budget spectrum but offer excellent durability and a unique patina. They are best avoided in sea climates due to potential corrosion issues.

Ensuring your budget aligns with the material’s performance and maintenance needs is vital for long-term cost efficiency.

Aluminum is the most affordable option, while copper and zinc offer premium quality at a higher price

When considering the maintenance requirements of your industrial seamless gutters, you need to factor in the material’s durability and resistance to elements. Aluminum gutters, while the most affordable, are relatively low maintenance as they resist rust and come pre-finished with a durable enamel paint, but they may require periodic inspections for damage from hail or extreme weather.

Copper and zinc gutters, although more expensive, offer superior durability but demand more meticulous care. Copper gutters develop a protective patina over time, which reduces maintenance needs, but they can be affected by acidic environments. Zinc gutters also form a protective patina, but they require caution in coastal areas or when combined with certain materials that can cause corrosion.

Regular cleaning, at least twice a year, is essential for all metal gutters to prevent clogs and guarantee peak performance, regardless of the material chosen.

Maintenance Requirements

To guarantee the longevity and efficiency of your industrial seamless gutters, regular maintenance is crucial, regardless of the material you choose. Here are some key maintenance tasks to secure your gutters remain in prime condition:

Maintenance Tasks:

- Clean Gutters Regularly: Clean your gutters at least twice a year, once in the spring and once in the fall, to prevent debris accumulation and clogs that can cause water overflow and potential damage to your roof or foundation.

- Inspect for Blockages and Damage: Check your gutters and downspouts after heavy rainstorms and every six months for signs of rust, cracks, or other damage. Repair any issues promptly to avoid more extensive problems.

- Flush Downspouts: Use a garden hose to flush out downspouts and clear them of debris to secure water flows freely.

- Check and Adjust Slope: Verify that your gutters are sloped correctly to allow water to flow efficiently toward the downspouts. Adjust the slope if necessary to prevent water pooling.

Copper and zinc require minimal upkeep, while aluminum and steel may need more frequent maintenance to prevent damage

When considering the aesthetic preferences for your industrial seamless gutters, it’s essential to weigh the maintenance requirements against the visual appeal. Copper and zinc gutters, known for their premium quality and natural patina, require minimal upkeep, as they are resistant to rust, warping, and corrosion, and can enhance their appearance over time. In contrast, aluminum and steel gutters, while more affordable, may demand more frequent maintenance to prevent damage from corrosion and wear, which can impact their aesthetic longevity. Understanding these differences helps you make an informed decision that balances your aesthetic goals with the practical needs of your facility.

Aesthetic Preferences

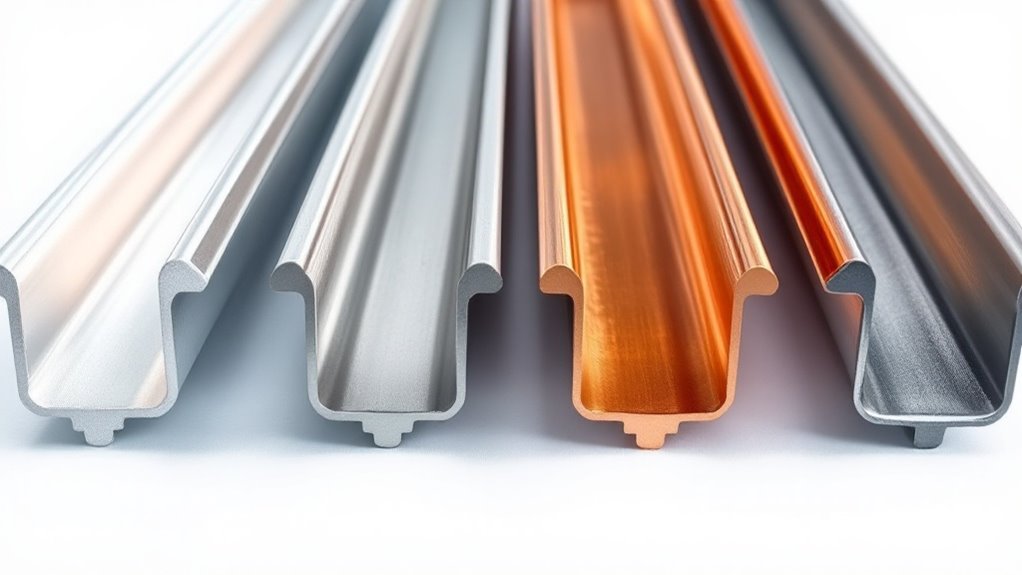

Aesthetic preferences play a crucial role in selecting the right material for your industrial seamless gutters, as they must align with the overall architectural design and maintenance requirements of your property. When choosing between aluminum, steel, copper, and zinc, consider how each material will visually integrate with your building.

- Color Options: Aluminum and steel gutters are available in a wide range of colors to match your building’s siding and trim. Copper and zinc, while fewer in color options, offer a distinctive, luxurious appearance.

- Material Finish: Copper gutters develop a beautiful patina over time, while aluminum and steel can have a sleek, metallic finish. Zinc gutters often have a soft, metallic sheen.

- Style Compatibility: Choose between K-style, half-round, and other profiles to complement your building’s architectural style. Make certain the gutter style aligns with the roofline and overall design.

- Visual Harmony: Select materials and colors that blend seamlessly with your building’s exterior to enhance curb appeal and maintain a cohesive look.

Copper is ideal for those looking for an upscale, distinguished look, while zinc offers a modern industrial aesthetic

When considering copper or zinc for your industrial seamless gutters, you should also think about the environmental implications. Copper, known for its natural, 100% recyclable properties, does not harm the environment and allows for safe rainwater collection for garden use. Zinc, similarly, forms a protective patina that resists corrosion and UV damage, ensuring long-term performance without adverse environmental effects.

Environmental Considerations

When selecting materials for industrial seamless gutters, environmental considerations are paramount. You need to choose materials that not only guarantee the durability and performance of your gutters but also minimize their ecological impact.

Here are some key environmental considerations for each material:

- Reduction in Material Waste: Seamless gutters, especially those made from aluminum, are custom-fit to minimize waste during installation, reducing the amount of material that ends up in landfills.

- Use of Recyclable Materials: Aluminum, steel, and other metals used in seamless gutters are highly recyclable, conserving natural resources and reducing the energy needed for raw material production.

- Longer Lifespan: Durable materials like aluminum and steel extend the lifespan of gutters, reducing the frequency of replacements and the associated environmental footprint.

- Energy Efficiency: The manufacturing process for seamless gutters, particularly those made on-site, can be more energy-efficient compared to producing sectional gutters.

Zinc is the most eco-friendly material, followed by aluminum, both of which are recyclable. Copper and steel also offer recyclability but have a higher environmental cost

When considering the most eco-friendly materials for your industrial seamless gutters, zinc and aluminum stand out for their recyclability and environmental benefits.

Environmental Impact Comparison

| Material | Recyclability | Environmental Cost | Energy to Produce | Maintenance Needs |

|---|---|---|---|---|

| Zinc | 100% | Low | Low | Minimal |

| Aluminum | 100% | Low | Moderate | Minimal |

| Copper | Recyclable | High | High | Minimal |

| Steel | Recyclable | High | High | Moderate |

Zinc is the most eco-friendly, being 100% recyclable and requiring less energy to produce and install. Aluminum follows closely, also fully recyclable with moderate energy requirements. While copper and steel are recyclable, they have a higher environmental cost due to their high energy demands and more complex production processes. This makes zinc and aluminum the preferred choices for those prioritizing sustainability and minimal environmental impact.

Conclusion

In essence, selecting the appropriate material for your industrial seamless gutters is crucial for ensuring durability, weather resistance, and long-term performance. Each material has its unique advantages and drawbacks.

- Aluminum: Lightweight, rust-resistant, and affordable, but may be thinner than steel and more susceptible to damage from hail.

- Steel: Durable and heavy-duty, but requires more maintenance to prevent rust, especially in galvanized forms. Galvalume steel offers improved corrosion resistance but may not be suitable for coastal areas.

- Copper: Highly durable and aesthetically appealing, but expensive. Copper gutters develop a protective patina over time but are not ideal for sea climates or with certain materials like cedar shingles.

- Zinc: Extremely durable with a protective patina, but more expensive than aluminum and not suitable for sea climates or with materials that produce acid runoff.

Choosing the right seamless gutter material depends on several factors including weather conditions, budget, maintenance needs, and aesthetic preferences. By considering the unique benefits of aluminum, steel, copper, and zinc, businesses can make an informed decision that will enhance their industrial property’s performance and curb appeal

Choosing the right seamless gutter material for your industrial property involves a careful evaluation of several key factors, including weather conditions, budget, maintenance needs, and aesthetic preferences. If you live in an area with harsh weather conditions, consider materials like steel or galvanized steel, which are strong and can withstand heavy rainfall and snow loads.

For budget-conscious decisions, aluminum and vinyl are more affordable options, though they may not be as durable as other materials. Aluminum is lightweight, rust-resistant, and comes in various colors, making it a popular choice.

Maintenance needs should also be considered; copper, while elegant and durable, requires professional installation and can be expensive. Zinc, on the other hand, is highly durable and resistant to corrosion, but it is also more costly.

Lastly, aesthetic preferences play a role; copper develops a unique patina over time, while steel and aluminum can be finished to match your property’s style. By weighing these factors, you can select a material that enhances both the performance and curb appeal of your industrial property.